[dropcap style=”dropcap2″]ConservAIR pressure boosters are designed for point-of-use applications requiring high pressure. Pressure boosters provide the advantage of delivering high pressure air to the point-of-use without having to elevate the entire plant pressure. ConservAIR pressure boosters are air-driven requiring no electricity, cooling water, or in-line lubricator, and are explosion proof.[/dropcap]

[dropcap style=”dropcap2″]ConservAIR pressure boosters are designed for point-of-use applications requiring high pressure. Pressure boosters provide the advantage of delivering high pressure air to the point-of-use without having to elevate the entire plant pressure. ConservAIR pressure boosters are air-driven requiring no electricity, cooling water, or in-line lubricator, and are explosion proof.[/dropcap]

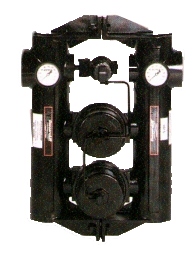

2:1 Pressure Booster

Conservair Point Of Use Pressure Booster

Positive Displacement Amplifier Boosts Air Pressure Supply At Points-Of-Use.

[grid_6 position=”alpha”]

Benefits

- Provides air pressure to critical points-of-use

- Eliminates down time and production loss caused by low air pressure

- Enables air equipment to operate at pressure levels specified by equipment manufacturers

- Cost Savings- Allows for the reduction of general plant air pressure when used in conjunction with ConservAIR’s Intermediate Control®

Minimum Maintenance

- Requires no external lubricators

- Integrated block design eliminates potential points of expensive leakage

- Includes high performance mechanical pump parts for long life

[/grid_6]

[grid_6 position=”omega”] [/grid_6]

[/grid_6]

[divider]

ConservAir Intermediate Controllers for Compressed Air

[grid_6 position=”alpha”]

The Intermediate Controller solution is simple and can be retrofitted to any compressed air system.

Yesterdays answer to fluctuating compressed air pressure was to add more compressors to the system. Many companies continue to make this costly mistake.

ConservAIR Technologies’ patented Intermediate Control compressed air management system addresses the problem of fluctuating air pressure where it counts – at your work stations.

Save Money

Fewer Compressors are required and/or compressors can be operated at lower settings. ConservAIR’s patented Intermediate Controller (I/C) pays for itself in energy savings alone, usually within the first six months to three years, depending on the size of your system and your current efficiency of operation.

Improve Production

- The I/C delivers stable air pressure to work stations at the lowest optimal pressure levels to:

- control compressors

- reduce compressed air leaks

- lower incidence of product defects and scrap

- improve consistency of finished product quality

- reduce operational downtime

- minimize or eliminate compressed air related complaints

Control Operating and Maintenance Costs

Better control of air flow through the system reduces stress on compressors and pneumatic equipment and minimizes leaks caused by unstable header pressure. Better compressor control results in substantially reduced equipment costs.

Reserve Air Supply

Reserve air supplies are always available to satisfy work station demands.

[/grid_6]

[grid_6 position=”omega”] [/grid_6]

[/grid_6]