What’s New

Atlas Copco Improves Three GA Series Rotary Screw Air Compressor Models

The improved GA 30+, 37 and 45 air compressors offer better performance, lower noise and a smaller footprint.

[grid_6 position=”alpha”]

[/grid_6]

[grid_6 position=”omega”]

[dropcap style=”dropcap2″]Atlas Copco has enhanced three air compressors in its popular GA series. The improved GA 30+, 37 and 45 compressors offer better performance, lower noise and a smaller footprint. The updated oil-injected rotary screw compressors are now available worldwide.

The free air delivery (FAD) and specific energy requirement (SER) of the GA 30+, 37 and 45 have both been improved by 1 percent. Each model now offers low noise levels down to 65 dB(a) for extremely quiet operation. The new GA 30+, 37 and 45 provide 30 percent smaller footprints than previous editions; the 60 hp version has a footprint as small as 52 inches long and 35 inches wide. The low noise levels and reduced size make it possible to install units on the work floor, sharply reducing the energy consumption of transporting compressed air to the point of use.

“At Atlas Copco, we are always finding new ways to further advance our world-class products,” said Alfred Piccolo, vice president of sales and marketing with Atlas Copco Compressors. “The updated GA 30+, 37 and 45 represent our commitment to bringing customers the best technology to support their applications.”

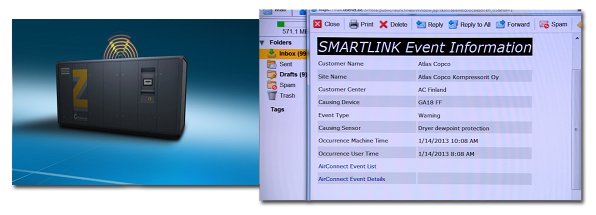

The GA30+, 37, and 45 are integrated packages with built-in refrigerant dryers. Each comes with an Elektronikon® controller and SMARTLINK® technology for remote monitoring. Due to their strong performance and durability, these compressors can be used in a variety of industrial applications, and in harsh environmental conditions and high ambient temperatures.

[/dropcap]

[/grid_6]